Technische Schaumstoffe aller Art für Industrie maßgeschneidert – Ihr Schaumstoff-Verarbeiter

Materialien

Verarbeitung

Einsatzbereiche

Aktuelles

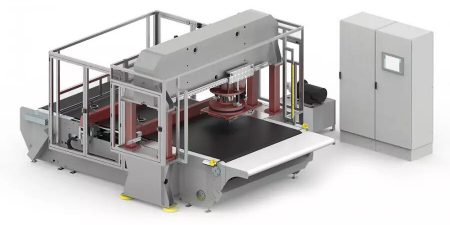

Höchste Produktivität dank individueller Stanzanlagen

Das Geschäft schläft nie und wir wollen unsere höchste Kompetenz immer weiter ausbauen. Deshalb haben wir unseren Maschinenpark mit zwei ...

weiterlesen Informationen aufgrund Russland-Ukraine-Konflikt!

Sehr geehrte Kund:innen, hiermit möchten wir Ihnen mitteilen, dass unsere Lieferkette zum derzeitigen Stand nicht vom Russland-Ukraine-Konflikt beeinträchtigt wird. Sollte ...

weiterlesen Spaltmaschine mit optischen Dickenmessgerät ausgestattet

PANA investiert weiter in die Modernisierung seines Maschinenparks. Die Spaltmaschine für Zellkautschuk, mit der auch Rollenwaren in verschiedenen Stärken hergestellt ...

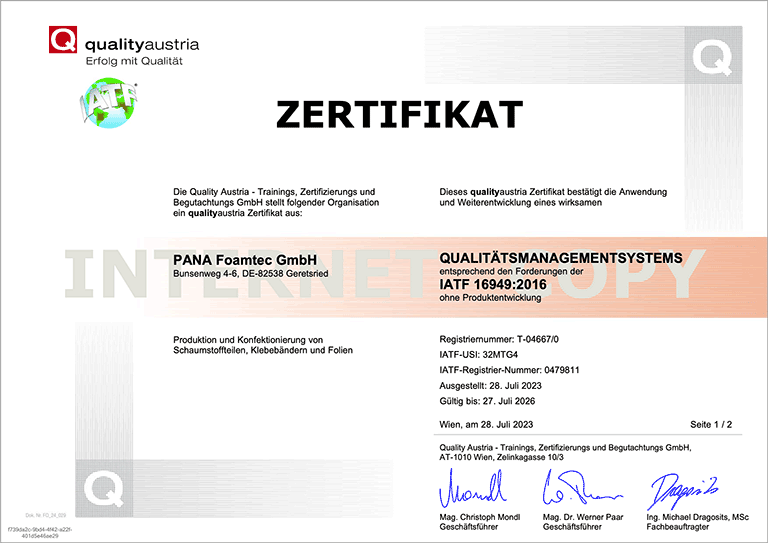

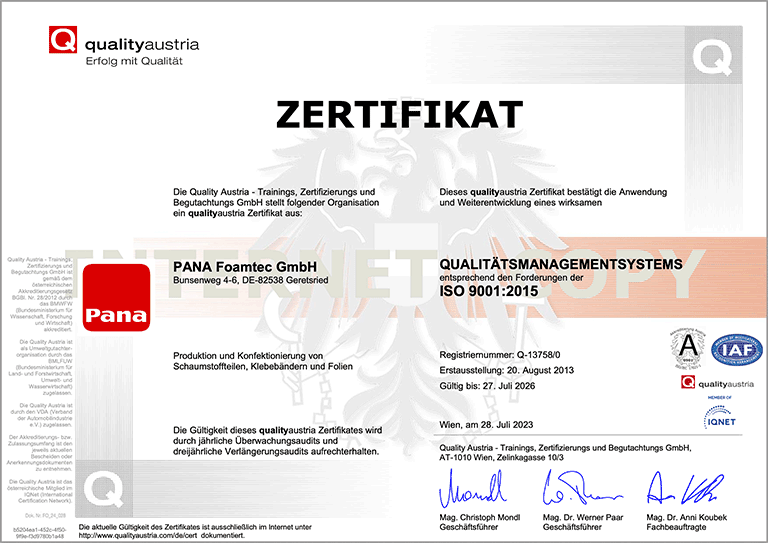

weiterlesen PANA Foamtec GmbH – Ihr zertifizierter und kompetenter Partner

Als langjähriger Partner der Automotive Branche, sind uns die anspruchsvollen Herausforderungen an Qualität der Produkte und Prozesse bewusst. Wir begleiten unsere Kunden vollumfänglich durch Null- und Vorserien, sowie Bemusterungen bis hin zur Serienlieferung. Mit unseren Zertifizierungen nach IATF 16949:2016 sowie ISO 9001:2015 können Sie sich auf gesicherte Prozesse jederzeit verlassen.